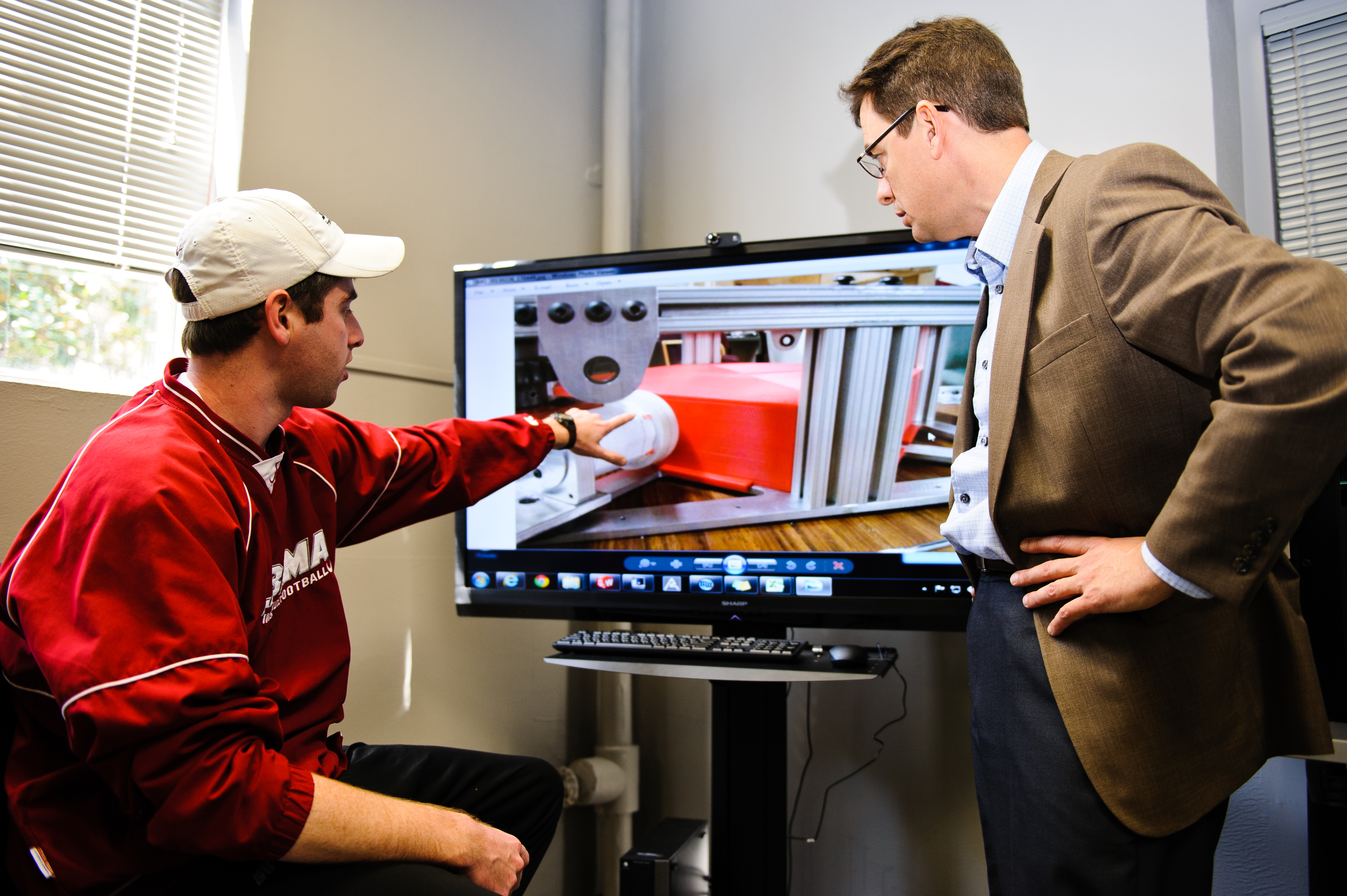

The UA 3D Prototyping Lab is open to anyone on campus to test the bounds of additive manufacturing, or 3D printing. The lab is operated by the College of Engineering, and its staff can assist in printing models personally designed for class, design groups, research, senior designs or personal use.

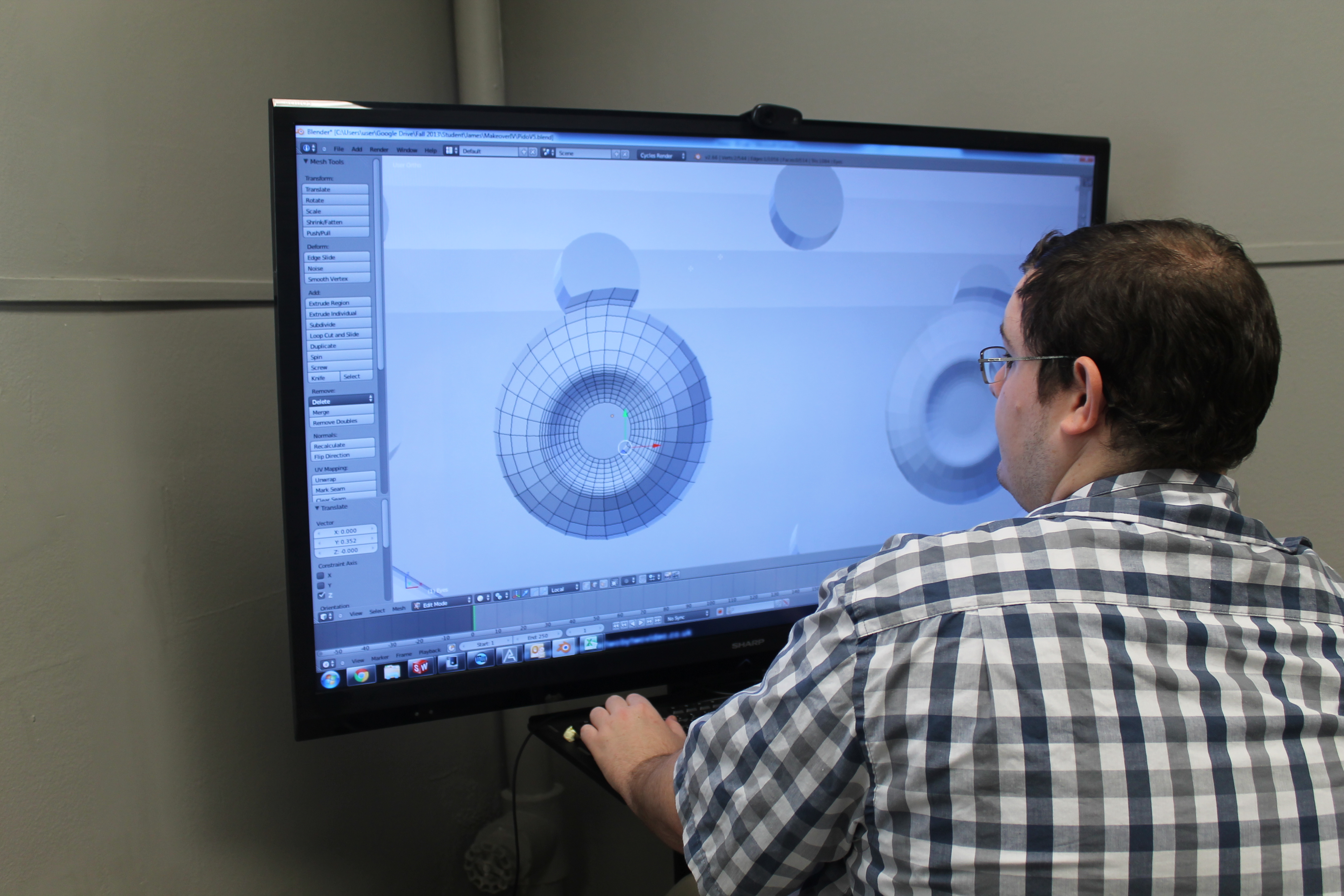

The team aims to promote efficient access to quality 3D production. The lab can receive a design created in one of the supported software programs and print the part, reducing manufacturing or shipping delays.

The lab reserves the right to refuse printing questionable objects including, but not limited to, weaponry, copyrighted materials or parts intended for commercial sale.

The College of Engineering set up the UA 3D Prototyping Lab to better prepare students for the sorts of environments they will see when entering the work force and help them develop the skills critical in getting products to market.

Any student, staff or faculty member on campus can use the lab’s three printers by submitting a design.

The lab is managed full time by students from within The University of Alabama with oversight from a staff technician and member of the engineering faculty. The staff controls the printing process to maximize the use of the printers.

Staff can:

Drawings will be checked against images from the Internet to ensure there is no copyright or restriction. Users are asked to modify downloaded files to ensure they are original.

Files for printing parts can be submitted by coming to the lab to upload the file.

When submitting a part, please include:

Original design files submitted should be .STL file to be used by the printers or .WRL file if full color is needed. The lab staff can help generate these files.

The lab reserves the right to refuse printing questionable objects including, but not limited to, weaponry, copyrighted materials or parts intended for commercial sale.